TECHNICAL DETAILS

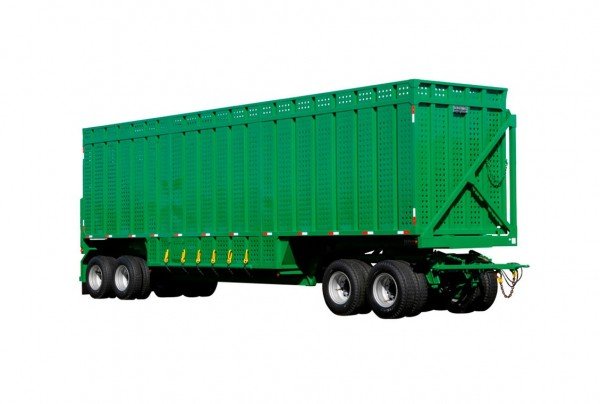

- Angle of rest to meet the filter cake in the most varied conditions of humidity and granulometry (mixed compound / chicken litter);

- Hydraulic capacity (force and stroke) for the multiload;

- Unloading height that allows: ↑ “windrow” height> yard savings;

- Unloading position and devices that keep the products deposited next to the wheels, without entering under the area of the wheelset or the composition;

- Flat central chassis made of high-strength material, with reinforcements capable of withstanding the lifting of the dimensioned load;

- Enable unloading with the driver in the cabin, avoiding the driver's getting off for unloading (reducing the need for EPIS placement/removal, such as: gloves, glasses, ear protector, leg protector, bonnets, helmets, in addition to not exposing the driver to dust and/or rain);

- Structural strength (↓weight x ↑resistance) to support the applied load, seeking to comply with the current legislation;

- Internal box angles suitable for reducing stress forces, with suitable corners.

- Optimized geometry of the boxes in order to meet the width and height of conventional loader shovels, suitable for loading in tippers with molds, eliminating the need for loading devices, such as: ditches, ramps, etc;

- Cargo boxes assemble in tubes and high resistance plates, so that continuous welds are made in the entire length of the cargo box, sealing the structure;

- The lifting of the cargo boxes is carried out by telescopic pistons (03 units per box) with two stages and activation by double action;

- Electro hydraulic control with lever and activation by wireless remote control (optional) providing greater safety for the user;

- Wheels: steel or aluminum (lighter and more resistant);

- Brake System: ABS / Tubeless, “S cam” system with two power lines, one for service and the other for emergency and spring-brake on one of the axles, bringing greater safety to the user;

- All the mechanical parts are reinforced so that the customer has a lower maintenance cost;

- Mechanical suspension;

- Gannet with manual or pneumatic activation;

- LED electrical installation (ensuring greater durability);

- Cleaning with chemical degreaser and phosphating;

- Painting in a P.U. system;

- Metal fenders, with rubber lamers.

Nossos

Diferenciais

01.

Produtos dentro das normas

02.

Atendimento Rápido

03.

Manutenção de qualidade

04.

Ampla linha de produtos

05.

Suporte qualificado

06.

Produtos exclusivos

Ficou

interessado?

Clique no botão, preencha o formulário

que em breve retornaremos o contato

Solicite seu Orçamento

Preencha o formulário abaixo. É rápido. * Campos obrigatórios